Compressed Air Dryers

AFE dryers utilise reliable adsorption technology, offer uninterrupted drying capacity and provide security to your production operations. Solutions for pure and dry air, when and where you need it.

The Problem.

Compressed air is a commonly used power source. Over the years it became a crucial part of a wide range in industrial processes. However, compressed air after compression is not clean and contains impurities like water, oil, dirt, wear particles and so on. This mixture creates a form of condensate which damages downstream equipment like air tools, pneumatic cylinders and other pneumatic equipment. It also causes high product rejects, high maintenance and costly air leaks in compressed air systems. The use of highly efficient compressed air filters and condensate drains will remove a lot of these impurities and can eliminate most of the problems downstream.

For various applications, this is not clean enough. Some applications may need an even higher level of compressed air quality.

Our Solution.

Utilising a reliable technology, the compressed air adsorption dryers provide the security to run the process without interruption and to have safe and reliable operations of downstream machines and air tools. The AFE adsorption dryers have a long service life and utilise high-performance desiccant which can reach a very low pressure dew point at a high input temperature.

Looking for a new custom compressed air dryer?

Key in your dryer requirements below to send us a quick enquiry. Our sales team will get back to you as soon as possible with the suitable model and product details that suit your needs.

Customisable Solutions

AFE Dryers are designed to your specific compressed air requirements. Our engineering team offer the best solutions to help you achieve energy savings, cost savings and optimised productivity.

Reliable Performance

Our adsorption dryers are simple in design, reliable in performance and deliver exceptional air quality. Easy to maintain - AFE dryers help you protect your investment, equipment and processes.

Rigorous Quality Control

AFE products comply with the European Pressure Equipment Directive (PED2014/68/EU), the recommendations of ISO8573 and carry the CE mark - ensuring top quality, safety and reliability.

C-HDD-N Compact Heatless Adsorption Dryers

- capacity from 0.14 - 2.7 m3/min (4.9 - 95.3 cfm)

- pressure dew point of down to -70°C (-94 °F)

- maximum operating pressure of 16 barg(232 psi)

- simple in design and reliable in performance

- advance PCB control with energy saving feature

C-HDAD-N Compact Heatless Adsorption Dryers With Carbon Tower

- capacity from 0.14 - 2.7 m3/min (4.9 - 95.3 cfm)

- pressure dew point of down to -70°C (-94 °F)

- 0il vapour removal down to 0.003 mg/m3

- maximum operating pressure of 16 barg (232 psi)

- designed for smaller CDA systems or point-of-use application

- simple in design and reliable in performance

- advance PCB control with energy saving feature

HDD Twin Tower Heatless Adsorption Dryers

- capacity from 2.3 - 70.0 m3/min (81 - 2,472 cfm)

- pressure dew point of down to -70°C (-94 °F)

- maximum operating pressure of 16 bar g (230 psi)

- simple in design and reliable in performance

- advance PCB control with energy saving feature

- optional HDAD with activated carbon tower

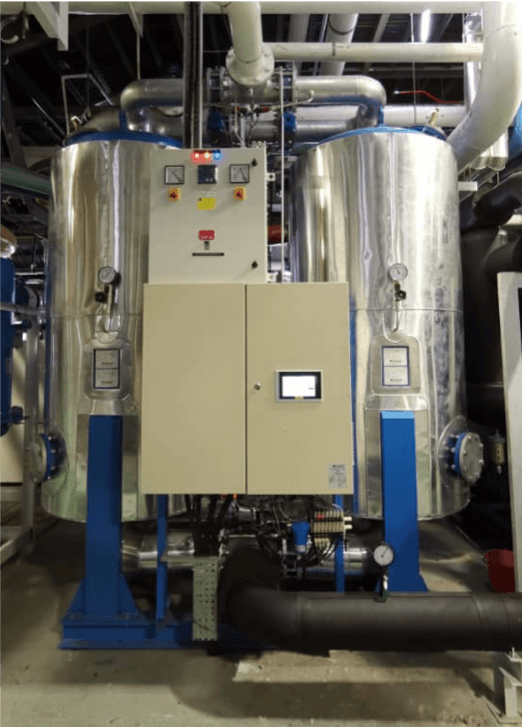

VEHDD Twin Tower Heated Adsorption Dryers (Zero Purge)

- capacity from 13.3 m3/min (470 cfm) and above

- pressure dew point down to -70°C (-94 °F)

- maximum pressure of 10 barg (230 psi)

- advance PLC touch-screen control with energy saving feature

- zero purge vacuum regeneration system (other system available upon request)

- optional IoT cloud connected PLC system for real-time remote monitoring

Remote Monitoring IoT Solutions

- optional IoT real-time remote monitoring for PLC dashboard

- cloud connectivity through Ethernet (via WiFi or 4G modem and SIM card)

- secure cloud-based dashboard provides 24/7 status overview

- accurate monitoring for predictive maintenance and timely servicing

- alarm and warning system linked to email notification

Photo Gallery

Our satisfied customers with their successful product installations.

Related Products

Explore our range of compressed air treatments products. Clean & Dry air begins with Us!